Product/Service

At our forefront in semiconductor ATE interface hardware design and manufacturing, we specialize in creating cutting-edge load boards and probe cards. Our commitment to excellence is underscored by a customer-centric business culture, ensuring unparalleled satisfaction and innovation in every product and service we deliver.

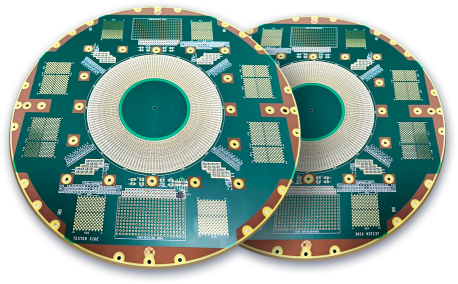

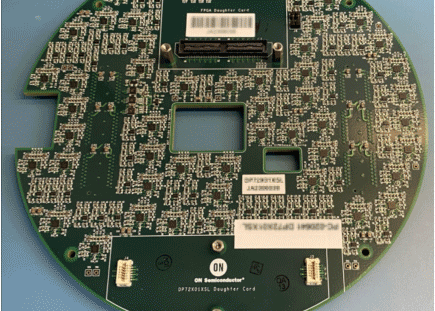

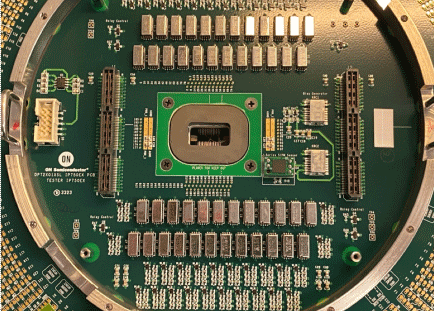

ATE Probe Card:

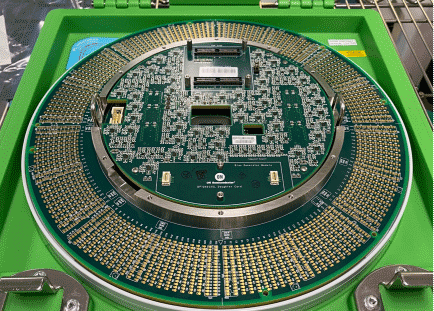

● What is probe card - probe card comes in between the DUT (device under testing) and an ATE tester to provide the electromechanical interface for wafer level (before packaging) sorting. Probe card provides the benefit to remove "bad" dies before they enter into packaging process, to save the total cost of testing.

● Why us: similar reasons with load board, and more: we keep working with the world's most prominent probe/needle material suppliers to stay on state-of-the-art and provide innovative solutions to our customers. We deliver solution with speed even if you only need 1 piece board.

● Our success story: we co-design with a world-famous manufacturer who develops probe/needle based on MEMS technology to develop specific applications that can be integrated in our interface boards to meet end-customer testing requirements. This unprecedented collaboration enables our customer to enjoy significantly shorter lead time, our partner a broader application of their technology, and of course win us customer satisfaction and loyalty!

Advancements in semiconductor Automated Test Equipment (ATE) probe cards have likely continued, here are some insights on the trends.

Technology Updates

Advanced MLO technology

- High-Density Interconnect (HDI) Technology:

HDI technology in MLO substrates allows for finer pitch and higher routing density, enabling the integration of more complex circuitry into smaller spaces. This can lead to more compact and efficient ATE designs.

- Improved Signal Integrity:

Advances in MLO technology may focus on enhancing signal integrity, reducing crosstalk, and minimizing losses. This is crucial for maintaining the accuracy of high-speed digital signals in semiconductor testing.

- Material Innovations:

Ongoing research and development in materials for MLO substrates may lead to improved thermal performance, better electrical properties, and increased reliability.

- High-Density Interconnect (HDI) Technology:

High parallelism

High parallelism probe cards have gained prominence in the industry, allowing simultaneous testing of multiple semiconductor devices on a single wafer. This technology update has significantly increased throughput and reduced testing time, thus improving manufacturing efficiency. Advanced probe cards can now accommodate a higher number of DUT (device under test), making them invaluable for high-volume semiconductor production.

Thermo-Mechanical Stability

As semiconductor devices continue to shrink, the demand for higher precision and control in testing has grown. Competitive probe card suppliers have responded to this need by enhancing the thermo-mechanical stability of their products. Innovative designs and materials, such as mechanical simulation (Finite Element Analysis) and thermal simulation have resulted in probe cards that can maintain contact integrity over a wide temperature range, ensuring accurate and consistent testing results under varying conditions.

Advanced Contact Technologies

One of the most crucial aspects of probe card technology is the contact mechanism. Recent innovations have seen the introduction of advanced contact technologies, such as vertical, cantilever, and magnetic contacts. These innovations allow for improved electrical performance, better signal integrity, and reduced damage to delicate semiconductor devices. The choice of contact technology is tailored to the specific requirements of the semiconductor application.

Benefits of Choosing a Competitive Probe Card Supplier

Improved Yield and Quality

Selecting a competitive probe card supplier can significantly enhance the yield and quality of semiconductor devices. Our advanced probe cards provide more accurate testing, reducing false failures and improving overall product reliability. The resulting reduction in defective components can lead to substantial cost savings and enhanced customer satisfaction. Our particular focus on components/ material selection, manufacturing /assembly capability development and extensive tests ensures our delivers of good yield and quality.

Enhanced Efficiency and Throughput

We offer probe cards with cutting-edge technology that can greatly increase testing efficiency and throughput. We partner with world-class probe head company and enable our customer to access advanced contact technology. The use of multi-DUT probe cards, combined with optimized contact mechanisms, can significantly reduce testing time. This, in turn, enables semiconductor manufacturers to meet production demands more effectively and swiftly.

Cost Savings

While high-quality, technologically advanced probe cards may come at a premium, the long-term benefits far outweigh the initial costs. By choosing a competitive supplier like Semiroc, semiconductor manufacturers can reduce their total cost of ownership. The extended lifespan of probe cards, improved yield, and enhanced throughput all contribute to a more cost-effective testing process. Semiroc has developed superior design and supply chain capability to have cost advantages:

- We always optimize our interface design with the sense of cost in mind. By breaking the silos between our design department and supply chain operations, there is constantly feedback from the

- Supplier relationship management – by having developed strong relationships with key suppliers, our material and component supply enjoys competitive prices, terms and delivery schedules,

- Strategic inventory management build by Semiroc to minimize holding costs and reduce the risk of obsolete inventory and volatile market pricing,

- Our streamlined internal processes and automation tools have helped us to largely enhance accuracy and efficiency in order processing, inventory management, and other supply chain activities.

The semiconductor industry's continual advancement and growth require state-of-the-art testing equipment to ensure the reliability and quality of devices. Probe cards have evolved significantly, employing advanced materials, high parallelism, thermo-mechanical stability to meet the industry's ever-increasing demands. Choosing a competitive probe card supplier like Semiroc offers numerous benefits, including improved yield, enhanced efficiency and cost savings. As the semiconductor industry continues to evolve, it is evident that the choice of a strong probe card supplier like us plays a pivotal role in staying competitive and maintaining high product quality.

Contact our customer service team now to find answers to your questions.

CONTACT US