Product/Service

At our forefront in semiconductor ATE interface hardware design and manufacturing, we specialize in creating cutting-edge load boards and probe cards. Our commitment to excellence is underscored by a customer-centric business culture, ensuring unparalleled satisfaction and innovation in every product and service we deliver.

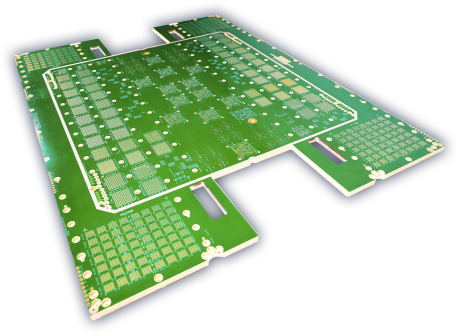

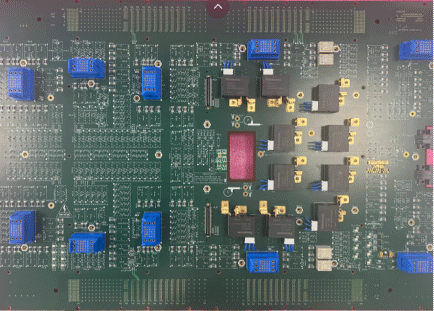

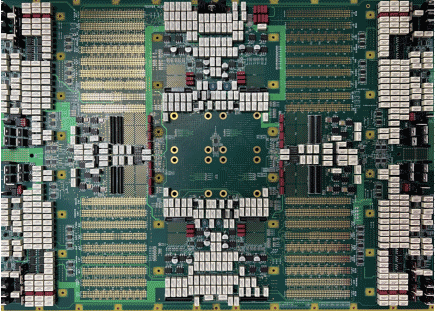

ATE Load Board:

● What is load board - load board comes in between the DUT (device under testing) and an ATE tester, provides mechanical support and electrical conductivity. lt is necessary for after-packaging IC testing.

● Why us: With extensive experiences (over 300 projects, 60,000 engineering hours delivered by design engineers of more than 10+ years working experience) on the leading test platforms from Teradyne, AdvanTest and AccoTest, we are proud to assure our customer with confidence that we provide high-performing boards with correct quality and good economics.

We have utterly extensive experience in Teradyne whole ETS series platform.

The semiconductor industry has been at the forefront of technological innovation for decades. Continuous advancements in semiconductor manufacturing processes have led to increasingly complex and sophisticated integrated circuits. As a result, the need for accurate and reliable ATE(Automated Test Equipment) solution has never been greater. One crucial component of ATE systems is the Load Board, which plays a pivotal role in the testing of semiconductor devices.

ATE systems are instrumental in ensuring the functionality and quality of semiconductor devices before they reach the market. These systems consist of various components, including test instruments, handlers, and load boards. The load board, in particular, serves as the interface between the DUT(device under test) and the ATE system. It provides electrical connections, mechanical support, and thermal management, making it a crucial element in the testing process.

Technology Updates

Miniaturization and High-Density Interconnects: The relentless drive for smaller and more powerful semiconductor devices has necessitated load boards to keep pace. Current technology updates include high-density interconnect solutions (eg. pin pitch<0.35mm, bump pitch<100um, high layer count>70) that accommodate an increasing number of contact points, enabling the testing of complex and densely packed chips.

Signal Integrity: As data rates and frequencies continue to rise in modern semiconductor devices, maintaining signal integrity is paramount. Semiroc has developed designs of innovative signal topology and detailed optimization through solid signal integrity understanding. On the other hand, next generation materials were continuously explored to maximize power and high frequency performance, for eg. thin core<=3mil, high speed/low loss materials, ensuring accurate and reliable test results.

Thermal challenge: Many semiconductor devices are highly sensitive to temperature variations. High-low temperature testing from - 40°C to 150°C is a must for those products aiming for reliability, for eg. medical and automotive industry. Load boards now incorporate advanced thermal solutions through thermal simulation and leverage low thermal expansion material to maintain consistent test result, minimizing the impact of temperature-induced performance variations.

Material Selection: The choice of materials for load boards is evolving to meet the industry's changing requirements. Advanced materials, such as high-frequency laminates and exotic alloys, are employed to enhance the load board's electrical performance, mechanical strength, and thermal characteristics. Semiroc enjoys access to technology development at the forefront, that are shared by our strategic partners, and has carried out a few semi-demonstration semi-engineering projects i.e. test vehicles that has superior performance. One example is Omron’s EFC(electro formed components) pin that provides high durability and long operation life and high inspection pass rate.

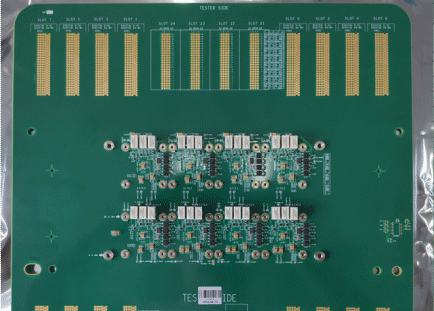

Modular and Configurable Designs: Flexibility is crucial in the semiconductor industry. Load boards with modular and configurable designs allow for faster customization to suit different DUTs, reducing time-to-market and development costs. We worked with different customers and supply them with flexible and reusable solutions eg. mother board + daughter board, or modules.

Benefits of Choosing a Competitive Load Board Supplier

Customization and adaptability: we offer customizable load boards that can be tailored to the specific needs of semiconductor manufacturers. For eg. when the customer needs a special coating, or has ultra-high-voltage requirement, or special-shaped etc. This adaptability ensures that load boards can accommodate a wide range of testing requirements

Cost-Efficiency: While we may not always offer the lowest upfront costs, we strive to provide better return on investment for our customers over the long term, by achieving superior performance, durability, and reduced operational expenses. Semiroc has developed superior supply chain capability to have cost advantages:

- We always optimize our interface design with the sense of cost in mind. By breaking the silos between our design department and supply chain operations, there is constantly feedback from the

- Supplier relationship management – by having developed strong relationships with key suppliers, our material and component supply enjoys competitive prices, terms and delivery schedules,

- Strategic inventory management build by Semiroc to minimize holding costs and reduce the risk of obsolete inventory and volatile market pricing,

- Our streamlined internal processes and automation tools have helped us to largely enhance accuracy and efficiency in order processing, inventory management, and other supply chain activities.

Reliability: we have a track record of delivering high-quality load boards that are built to last. We are committed to ensure the longevity and reliability of the equipment, reducing downtime and maintenance costs. Our particular focus on components/ material selection, manufacturing /assembly capability development and extensive tests ensures our delivers of good reliability.

Access to expertise: We have a group of highly skilled engineers and technical support teams to assist customers in optimizing their ATE systems. This expertise can be invaluable in achieving efficient testing processes. For eg. fast technical support response, telephone/on-site engineering support.

Time-to-market. Customer count on us, our engineers are well trained and rigorous on their work. We achieve first pass rate>=90% through:

- Design engineers’ rich design experience, combined with preliminary simulation and robust QC checks.

- Process control at the fab: Implement process control measures to monitor and control variations in the manufacturing process. This includes monitoring factors such as temperature, humidity, and other environmental conditions. Use Statistical Process Control (SPC) techniques to identify and address any process drifts that may impact testing outcomes.

- Continuous Improvement: Foster a culture of continuous improvement within the organization. Regularly review and update design, QC, manufacture procedures, equipment.

The semiconductor ATE Load Board industry is continuously evolving to meet the demands of an ever-advancing semiconductor industry. Choosing a competitive load board supplier can offer numerous advantages, including customization options, reliability, cost-efficiency, reliability, access to expertise and most importantly, time-to-market. As the semiconductor industry continues to push the boundaries of innovation, the role of load boards in ATE systems remains vital, and selecting the a competitive supplier like Semiroc is essential for your success in this fast-paced and dynamic sector.

Contact our customer service team now to find answers to your questions.

CONTACT US